[新しいコレクション] 0.2 yield strength calculation 369402

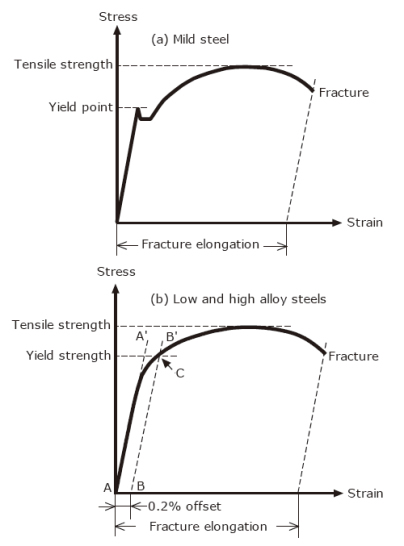

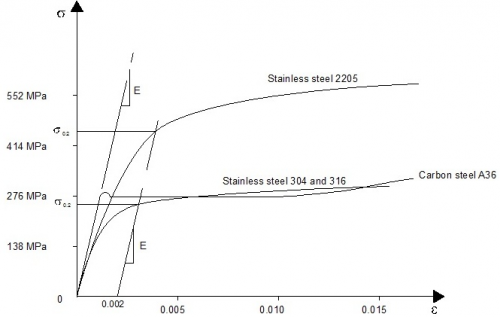

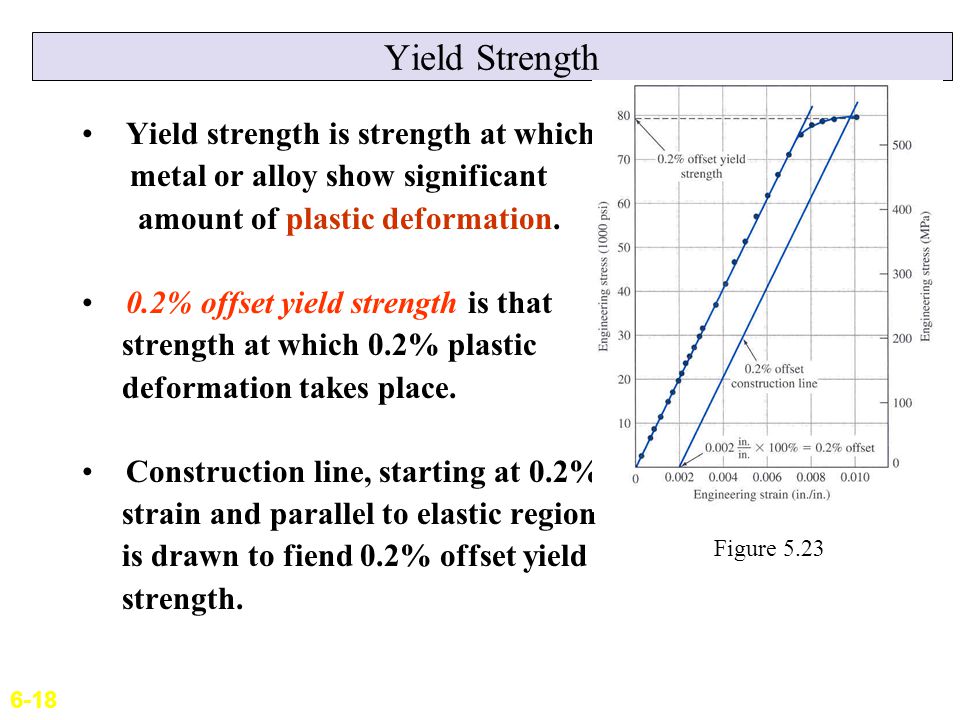

The 02% strain offset approach is mostly used to calculate the yield stress and serves as an efficient method for crosslab comparisons of measured material properties However, it is difficult to accurately determine the yield of the bone Especially when computational models require accurate material parameters, clarification of the yield point is neededFor me, yield stress (either 02% proof stress or upper yield stress depending on whether or not there is a yield point) is a special point in the stressstrain curve measured using a tensileFILM TYPE DENSITY (g/cc) YIELD of 1 MIL UNIT WEIGHT OF 1 MIL FILM;

How To Draw 0 2 Offset Line On A Stress Strain Graph Youtube

0.2 yield strength calculation

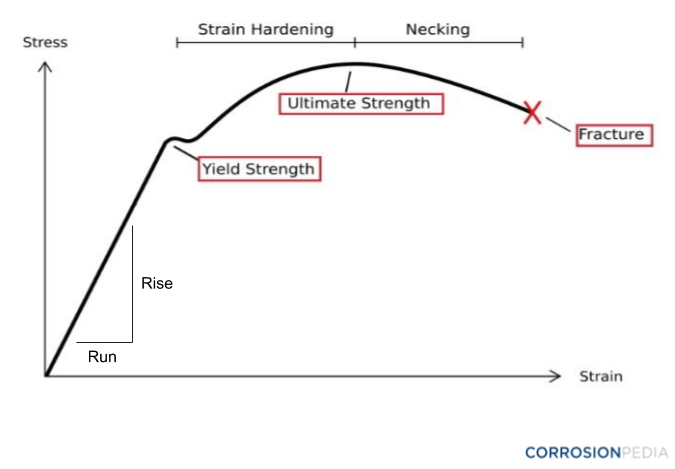

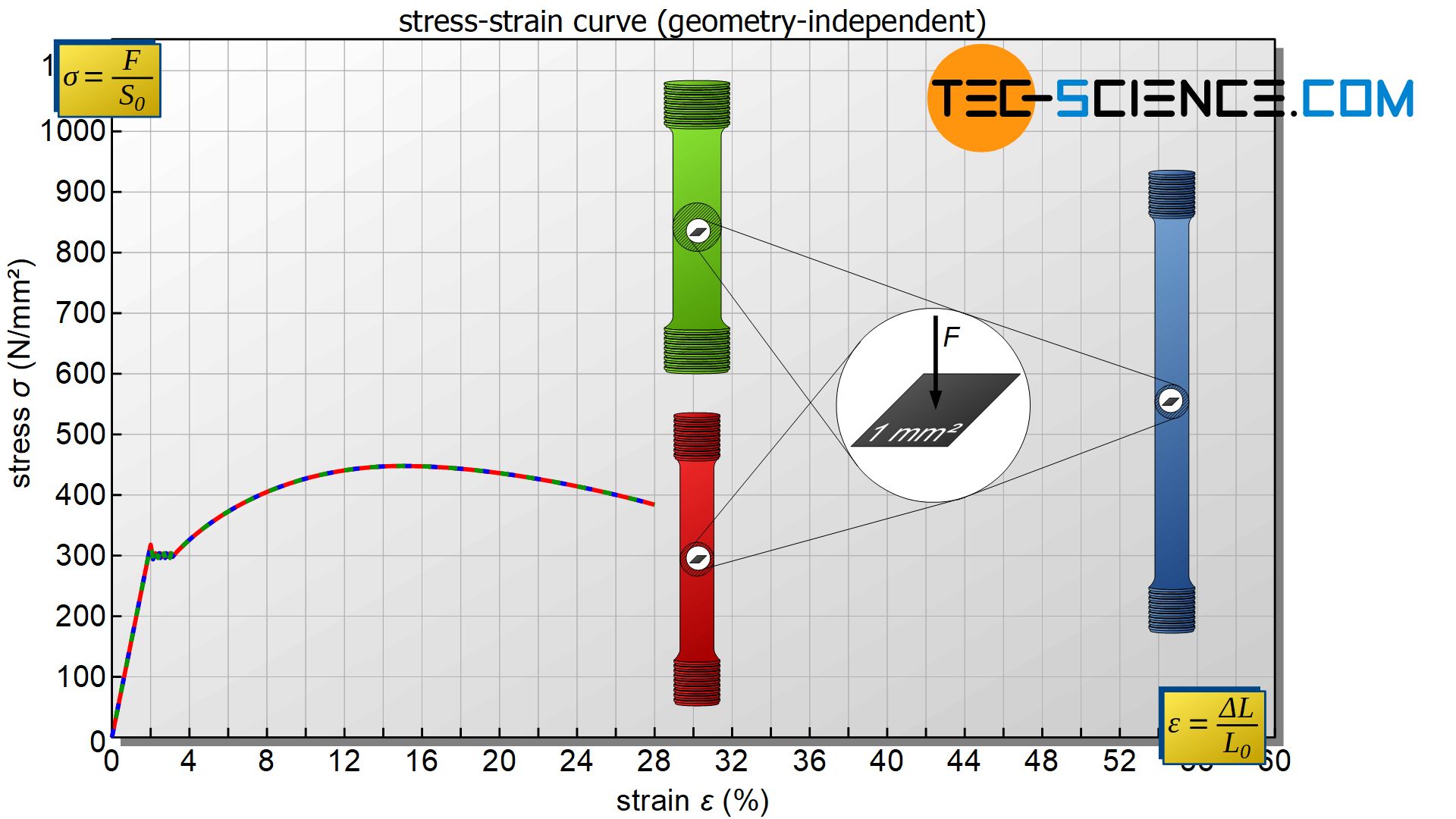

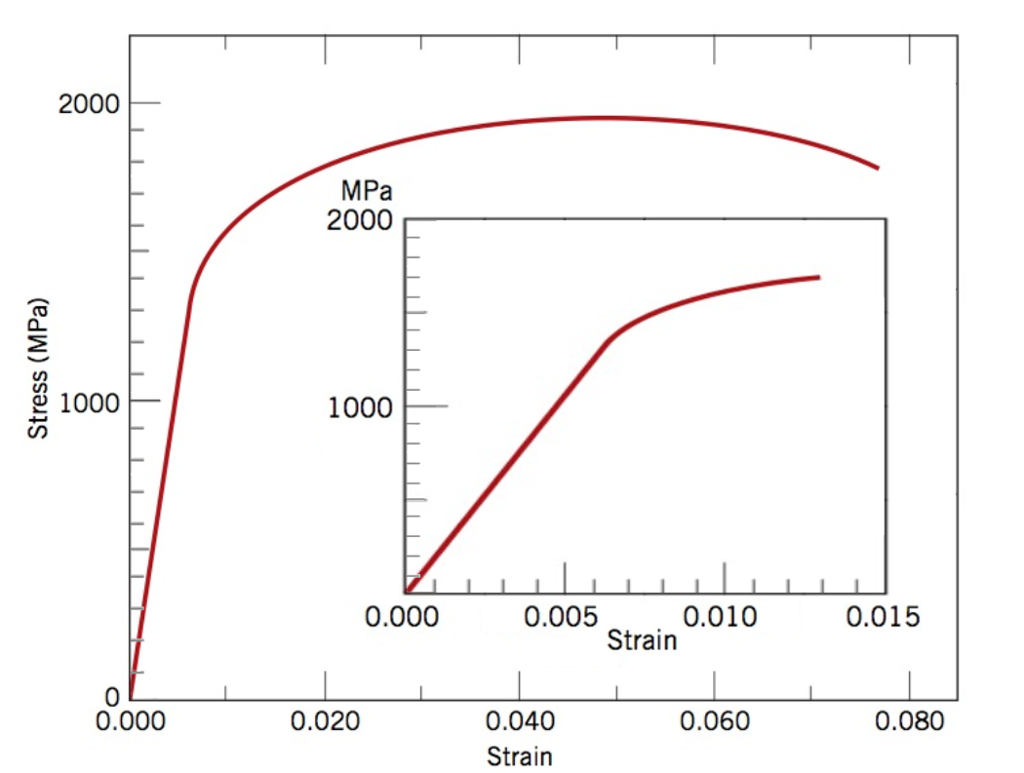

0.2 yield strength calculation-The stress which gives rupture is called the ultimate strength or the tensile strength;The 02% (0002) is a value of strain, which is arbitrary, but it covers somewhat the uncertainty of when a given material actually departs from the purely linear (elastic) relationship between stress and strain Let l = length, then strain ε = (l l o)/l o, where l o = original length (usually the gauge length)

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

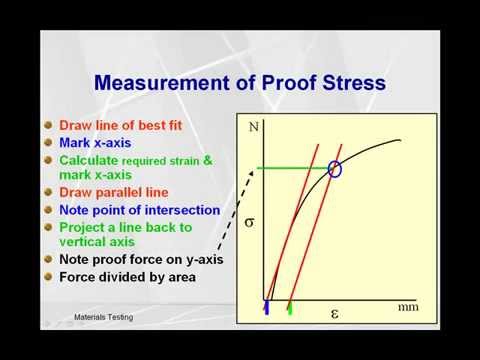

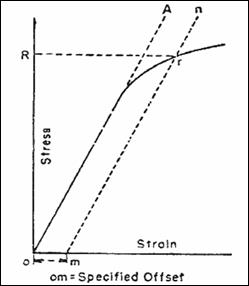

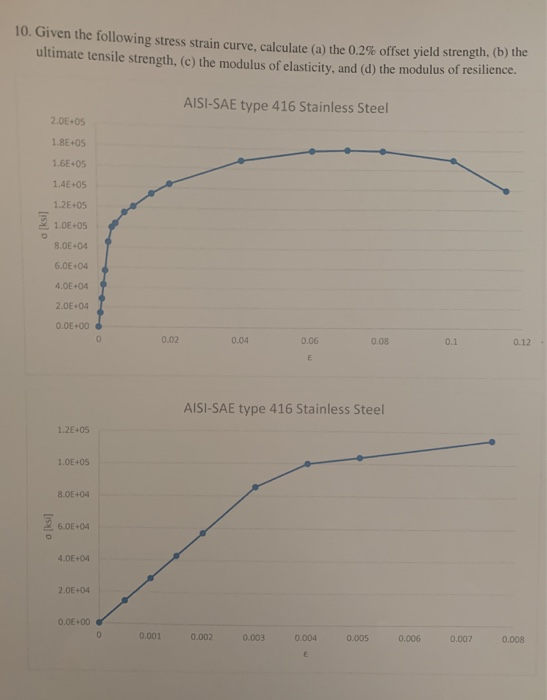

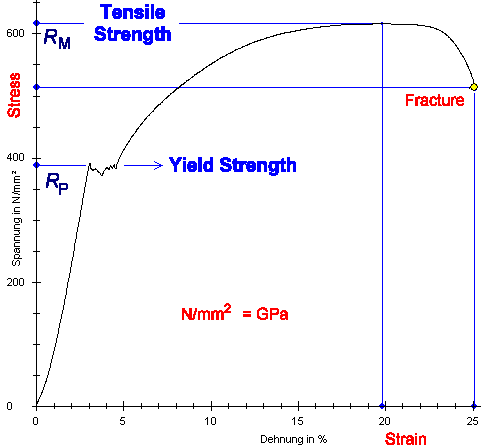

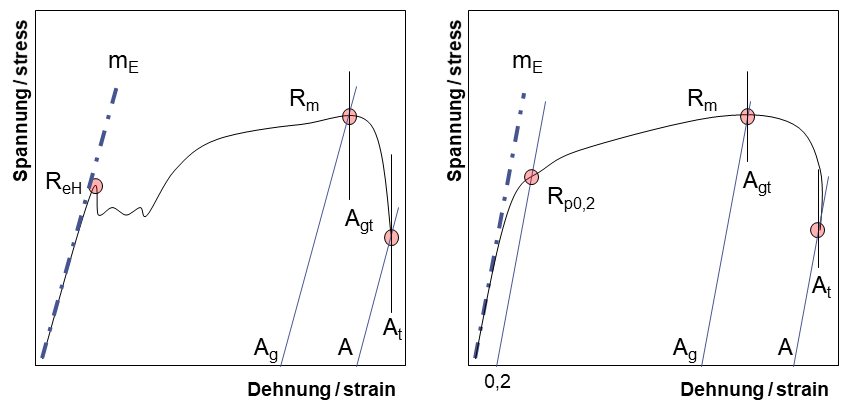

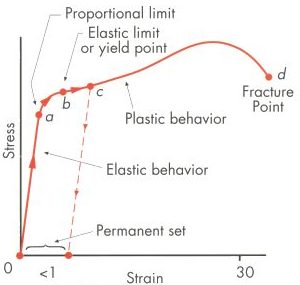

For the general engineering structural design, the yield strength is chosen when 0,2 percent plastic strain has taken place The 02% yield strength or the 02% offset yield strength is calculated at 02% offset from the original crosssectional area of the sample (s=P/A)Then on the stressstrain diagram, lay off om equal to the specified value of the offset (ie yield strength ~02%), draw mn parallel to OA, and thus locate r, the intersection of mn with the stressstrain curve corresponding to load R, which is the yield strength loadThe yield strength of 02% is offset, for example, by drawing through the point of the horizontal axis abscissa No 02% (or 0002), the line parallel to the initial straight part of the voltage chart Stress corresponding to the point in this result is defined as a yield strength of 02% compensated

A ss = 05 π d p L e = 05 π (D p ) L e To ensure that the screw fails before the thread strips it is necessary the the shear area is at least 2 times the tensile area ie L e (min) = 2 A t / 05 π(D p ) This assumes that the male and female thread materials have the same strengthThread Yield and Tensile Strength Equation and Calculator Fastener and Screw / Bolt Design, Formula and Calculations The following Equation and Calculator will determine the working loads base on the ultimate yield strength threaded connections ALL calculators require a Premium Membership Ultimate Strength of a thread y min = s yield x aFor to X use a strain value large enough that the line will be certain to cross the stressstrain curve You can then zoom in if you overshoot the curve by a lot

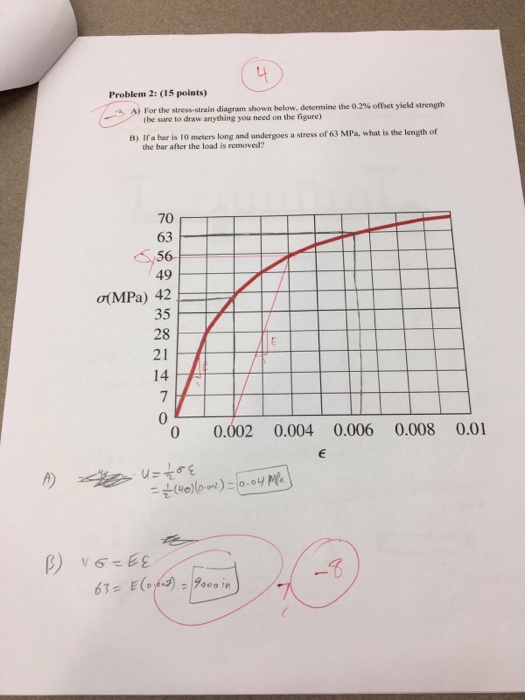

Determining 02% Offset Yield Stress (Capstone) How do I determine the 02% offset yield strength using the MTS and PASCO Capstone?Line XB is offset a strain amount OX that is typically 02% of the gage length Point C represents the yield strength by extension under load (EUL) and is found by constructing a vertical line YC Line YC is offset a strain amount OY that is typically 05% of gage length02% of 2525 = 0002 x 2525 = mm Which gives x 6125 = 3093mm of a shift This added to the original 01 crossing of your best fit line is about 32mm on the graph which seems way too far

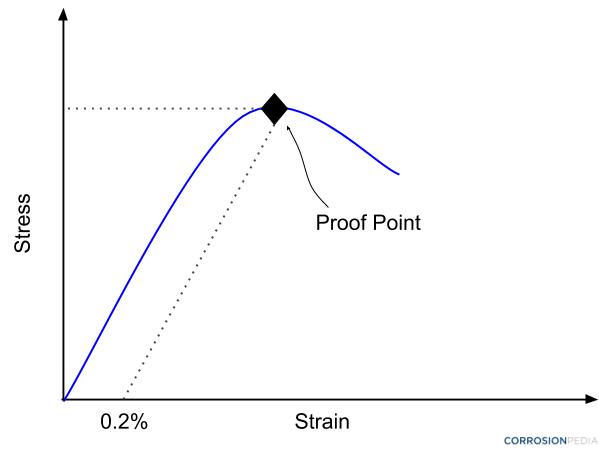

What Is A Proof Stress Definition From Corrosionpedia

How To Draw A Line Parallel To The Linear Portion Of The Curve In Excel Stack Overflow

I know for a stress vs strain curve, you have to have a 02% (0002) offset, but my Professor told me that the offset is not of the same value in a Load vs Displacement curve (which makes sense)Lbs Yp = minimum yield strength of steel;The 02% offset yield strength (02% OYS, 02% proof stress, R P02, R P0,2) is defined as the amount of stress that will result in a plastic strain of 02% This is illustrated by the blue line in Figure 1 below This is the yield strength that is most often quoted by material suppliers and used by design engineers If a

Sum Kee Metal Co Ltd

Mechanical Properties Of Materials Mechanicalc

In 2 /lb m 2 /kg lb/ream g/m 2;"Calculation of the increase in yield strength due to the effects of cold work of forming By How can I determine the 02% yield stress from my stressstrain graphs?For materials with no visible yield strengths in the stresscurves, a 02 % flexural offset yield strength \(\sigma_{by02}\) can be defined analog to the 02% offset yield strength of the tensile test This yield point is determined by the bending equation (\ref{biegegleichung}), although, the linear stress distribution is no longer

What Is The Difference Between Elastic Limit And Yield Point Physics Stack Exchange

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

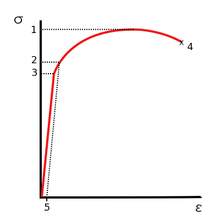

Different values may be obtained if tangents are drawn at different points Therefore, an offset yield point is obtained at a strain of 0002 (02%) A straight line is drawn parallel to initial portion of stressstrain curve at the strain value of 0002 and the point where it intersects the stressstrain curve is taken as yield pointThe quoted yield strength is determined by drawing a line parallel to the elastic loading curve, but with a 02% offset in strain The yield strength is the intercept of this line with the stressstrain curveConsider a screw of 05 inch diameter with 25 threads, find its tensile stress area A t = (314/4) * (05 * (1/25)) 2 = (0785)* (05 ) 2 = (0785)* () 2 = (0785)* = Therefore, the thread tensile stress area is in 2

Phy351 Ch 6

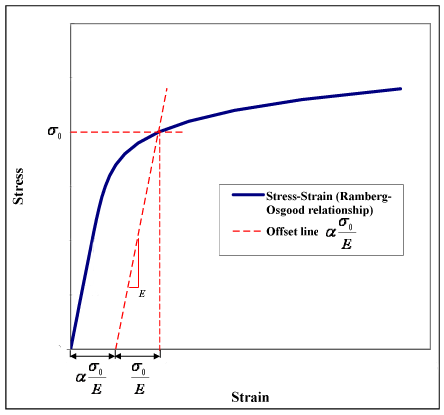

Ramberg Osgood Relationship Wikipedia

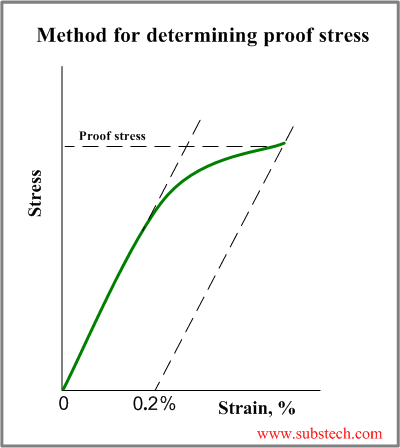

The conservative fit to these data leads to the following relationship between the lower bound estimate of UTS and yield or proof strength (σ y) (in N/mm 2 units) UTS/σ y = 1 2 (150/σ y) 25 Fig1 Determination of σy/UTS ratio from yield strength Examples are given in the table below σy (N/mm2) Lower bound estimate of UTS (N/mm2) 250 39002% offset method is a reliable and a convenient method for finding yield strength This off set yield (strength) is also called proof stress We draw a line parallel to the straight line portion of the stressstrain curve (which is essentially equal to slope of the graph ergo Young's modulus) at 02% of the original gauge length from 0 on the strain axisTensile Yield Strength Unit Conversion Calculator;

What Is A Proof Stress Definition From Corrosionpedia

Tensile Test And Stress Strain Diagram Substech

The stress which gives rupture is called the ultimate strength or the tensile strength;Proof stress is measured by drawing a line at 02% of the plastic strain, parallel to the straightline elastic region of the stressstrain curve The stress at the point where this line intercepts the curve is the proof stress The yield strength of a material can be increased by certain material processes Yield strength is measured atIt is shown that the 02 pct offset yield strength of a material (in kg per sq mm) can be obtained from simple hardness measurements using the expression σ y = (H/3)(01) m2 , whereH is the Diamond pyramid hardness andm is Meyer's hardness coefficient This expression holds for brass, steel in either the cold rolled or tempered condition, and aluminum alloys in either the cold rolled or

Www Asminternational Org Documents 059g Samplechapter Pdf D1a641ad E4e8 7d C565 C9c690c1931e

Bolt Torque Calculator General Technical Knowledge

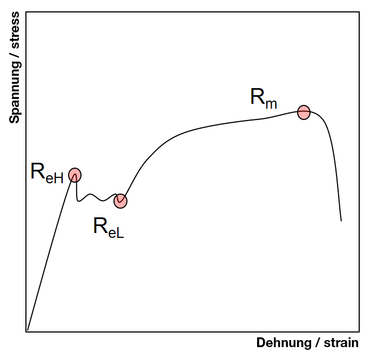

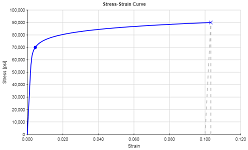

Example calculation (row 2) Cross sectional area of the specimen = 025 x 05 = 0125in^2 Original length of the specimen = " load = 1250lbs Stress = load/CS area = 1250/0125 = psi = 10ksi di view the full answerInquiry@TheGriffNetworkcom Mon – Fri 0am – 500pm EST Facebookf Twitter Youtube Linkedin Yield Tables For Film LPDE (Density 092) MICRON MIL G/SQ M G/MSF LBS/MSF SQ INCH/LB 25 1 230 47 36 15 331 68 2122 50 2 460 94 63 25 580 119 75 3 690 Yield Tables for Film Read More »Yield Strength – Yield Point The yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter6 Pdf

How To Draw A Line Parallel To The Linear Portion Of The Curve In Excel Stack Overflow

Due to the linear stress distribution at a bending load, the flexural yield strength for steels is about 10 % to % higher than the tensile yield strength!For example, "Yield Strength (at 02% offset) = 51,0 psi" Young's Modulus of Common Engineering Materials Some examples of yield strength for metals are as followsUnit Conversion Calculator & Converter for Tensile/Yield & Charpy values Use the following calculator to convert yield or tensile values in ksi, Mpa, N/mm² or psi Type the value in the box next to Mpa (using the drop down to change the unit of measurement)

Texture Analysis Professionals Blog Tensile Testing Using A Texture Analyser Calculating Fundamental Parameters

What Is Proof Stress Civildigital

Yield Strength is the stress a material can withstand without permanent deformation or a point at which it will no longer return to its original dimensions (by 02% in length) Whereas, Tensile Strength is the maximum stress (usually represented in PSI) that a material can withstand while being stretched or pulled before failing or breakingTypical strength of some common materialsRambergOsgood Equation The stressstrain curve is approximated using the RambergOsgood equation, which calculates the total strain (elastic and plastic) as a function of stress where σ is the value of stress, E is the elastic modulus of the material, S ty is the tensile yield strength of the material, and n is the strain hardening exponent of the material which can be calculated based on

Shear Yield Strength An Overview Sciencedirect Topics

Strength At Break Tensile

How do I determine the 02% offset yield strength using the MTS and PASCO Capstone?The conservative fit to these data leads to the following relationship between the lower bound estimate of UTS and yield or proof strength (σ y) (in N/mm 2 units) UTS/σ y = 1 2 (150/σ y ) 25 Fig1 Determination of σ y /UTS ratio from yield strengthThe yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at

Engrapps Burst And Collapse Pressure Vessel Design

Strength And Stiffness Characteristics

If you had a Load (yaxis) vs Displacement (xaxis) curve, how do you calculate the yield strength?The stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offsetDue to the linear stress distribution at a bending load, the flexural yield strength for steels is about 10 % to % higher than the tensile yield strength!

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Cee 3710 Strength Versus Stiffness

The equation we want is simply (in this case) "*(x00)" (00 microinches/inch = 02% strain) For the from X value use 00 (or any smaller value);Typical strength of some common materialsLine XB is offset a strain amount OX that is typically 02% of the gage length Point C represents the yield strength by extension under load (EUL) and is found by constructing a vertical line YC Line YC is offset a strain amount OY that is typically 05% of gage length

Materials Testing Glossary Admet

Correlation Between Engineering Stress Strain And True Stress Strain Curve

BOPP 0906 30,600 435 141 23 LLDPE (Linear Low Density Polyethylene 092The yield strength is the pressure value of the yield point For the material that is not obvious yield, the stress value that produces 02% permanent deformation is often referred to as the yield strength ⑤ Shear Strength It refers to the maximum load of the original crosssectional area of the shear area before the sample shearsOnce you have determined the Young's Modulus for the experimental run, y

Q Tbn And9gcrhvogkniaf5aix Yv5viz777uqklm0zjg52gijgphwvl7khodo Usqp Cau

Yield Strength Strength Mechanics Of Materials Engineers Edge

Where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x Lw Smaller governs the strength of the weld Always check weld metal and base metal strength Smaller value governs In most cases, theThe 02 Percent Offset Rule The most common engineering approximation for yield stress is the 02 percent offset rule To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material \sigma = 0002\times E σ = 0002×EThe strength of a material is determined by the tension test which measure the tension force and the deformation of the test specimen the stress which gives a permanent deformation of 02% is called the yield strength;

Ultimate Tensile Strength Wikipedia

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter6 Pdf

For the genera structural design, the yield strength is chosen when 0,2 percent plastic strain has taken place The 02% yield strength or the 02% offset yield strength is calculated at 02% offset from the original crosssectional area of the sampleOnce you have determined the Young's Modulus for the experimental run, you can then enter this data into the calculator to set the slope of the 02% offset line Next, you can use the Smart Tool to find the value of the coordinate of the experimental stressstrain curve to determine the yield point for the materialFor example, "Yield Strength (at 02% offset) = 51,0 psi" Young's Modulus of Common Engineering Materials Some examples of yield strength for metals are as follows Typical StressStrain Curve Plastics Alternate values are sometimes used instead of yield strength Several of these are briefly described below

How To Calculate Yield Point At 0 2 In Stress Strain Curve Quora

Solved For The Stress Strain Diagram Shown Below Determi Chegg Com

RambergOsgood Equation The stressstrain curve is approximated using the RambergOsgood equation, which calculates the total strain (elastic and plastic) as a function of stress where σ is the value of stress, E is the elastic modulus of the material, S ty is the tensile yield strength of the material, and n is the strain hardening exponent of the material which can be calculated based onFor materials with no visible yield strengths in the stresscurves, a 02 % flexural offset yield strength \(\sigma_{by02}\) can be defined analog to the 02% offset yield strength of the tensile test This yield point is determined by the bending equation (\ref{biegegleichung}), although, the linear stress distribution is no longerFor the general engineering structural design, the yield strength is chosen when 0,2 percent plastic strain has taken place The 02% yield strength or the 02% offset yield strength is calculated at 02% offset from the original crosssectional area of the sample (s=P/A)

Strength At Break Tensile

Estimating Tensile Strength From Yield Or 0 2 Proof Values Twi

The API pipe body strength is the axial load required to yield the tube This equation does not reduce the body strength of a tubular for tolerances on dimensions or for the API yield point anomaly P = 0784 * Y* D2 d2 y p Py = pipe body yield strength;The strength of a material is determined by the tension test which measure the tension force and the deformation of the test specimen the stress which gives a permanent deformation of 02% is called the yield strength;About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators

Stress Versus Strain

Yield Strength Strength Mechanics Of Materials Engineers Edge

02% Offset The 02% offset point is determined by drawing a line parallel to the linear region of the curve starting from point 0002 on the strain axis The intersect of this line and the stressstrain curve defines the 02% yield pointThe yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically The value for this is commonly set at 01% or 02% plastic strainThe yield strength of 02% is offset, for example, by drawing through the point of the horizontal axis abscissa No 02% (or 0002), the line parallel to the initial straight part of the voltage chart Stress corresponding to the point in this result is defined as a yield strength of 02% compensated

Material Properties Simsolid

Calculate Proof Stress Youtube

Yield Point Yield Point Ratio Offset Yield Zwickroell

Yield Strength Of Plastics Basic Principles The Tensile Test And Material Property Table Engineeringclicks

Materion Com Media Files Alloy Newsletters Technical Tidbits Issue No 47 Yield Strength And Other Near Elastic Properties Pdf

Solved B Calculate The 0 2 Offset Yield Stress In Gpa Chegg Com

Yield Strength Strength Mechanics Of Materials Engineers Edge

What Is Tensile Testing Instron

How Can I Determine The 0 2 Yield Stress From My Stress Strain Graphs

Stress Strain Curves Of Metallic Materials And Post Necking Strain Hardening Characterization A Review Tu Fatigue Amp Fracture Of Engineering Materials Amp Structures Wiley Online Library

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Http Web Mit Edu Dlizardo Www Uniaxialtestinglabreportv6 Pdf

Http Maecourses Ucsd Edu Jmckittr Mae Wi11 Assignment 5 solutions Pdf

Http People Virginia Edu Lz2n Mse9 Solutions Solutionshw4 Pdf

Aluminum Sample 9

Q Tbn And9gctox3cf4zpt H1tpvycayerw3xbv Ukqszfzrag5mxfqpo7il42 Usqp Cau

Yield Strength Yield Point Stress Strain Curve

Stress And Strain Mechanical Properties Of Materials

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Link Springer Com Content Pdf 10 1007 Bf Pdf

After Fracture The Total Length Was 47 42 Mm And The Diameter Was 18 35 Mm Plot The Engineering Brainly Com

Finding 0 2 Offset Strain Dplot

Stress Versus Strain

How To Draw 0 2 Offset Line On A Stress Strain Graph Youtube

Steel Material Properties Steelconstruction Info

Solved 10 Given The Following Stress Strain Curve Calcu Chegg Com

Nondestructive Evaluation Physics Materials

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

What Is 0 2 Of Offset Method In Yield Strength Quora

4 A Force Of 000 N Will Cause A 1 Cm X 1 Cm Bar Of Magnesium To Stretch From Course Hero

Engineering Stress Strain Curve

Finding 0 2 Offset Strain Dplot

Determining 0 2 Offset Yield Stress Capstone Video Library Pasco

Tensile Property Testing Of Plastics

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

Gvvy2hhnalj6dm

Http Www Schooloftesting Com Download How To Interpret Stress Strain Diagrams How to interpret stress Strain diagrams Pdf

Yield Engineering Wikipedia

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Engarc L Offset Yield Method

Determining 0 2 Offset Yield Stress Capstone Video Library Pasco

Science Of Uniaxial Deformation

Yield Point Yield Point Ratio Offset Yield Zwickroell

People Engr Ncsu Edu Ytzhu Class Teaching Mse0 Lecture7 Sept16s Pdf

Yield Point An Overview Sciencedirect Topics

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Why Do We Use 0 2 Offset In Aluminum Stress Strain Curve Quora

Http Www Csun Edu Bavarian Courses Mse 527 Tension Test Mse 527l Pdf

Q Tbn And9gcslkabgihai7oiceudovf Kl Msyzmkrbolgngnin4hsqzr2pre Usqp Cau

Load Extension Diagram Leaving Certificate Engineering Notes

Http Www Schooloftesting Com Download How To Interpret Stress Strain Diagrams How to interpret stress Strain diagrams Pdf

Stress Strain Curve Calculator Mechanicalc

Mechanical Testing Tensile Testing Part 1 Twi

What Is The Difference Between 0 2 Yield Stress And Yield Stress In Aluminum Quora

Determining The Flow Stress Curve With Yield And Ultimate Tensile Strengths Part I

Yield And Tensile Strength Engineering Materials Youtube

Link Springer Com Content Pdf 10 1007 Bf Pdf

Mechanical Properties Of Metals I Ppt Download

Solved A Using The 0 2 Strain 0 002 Strain Offset Met Chegg Com

Ductile Iron Data Section 3 Part 1

Offset Yield Strength Instron

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Why If The True Stressstrain Data Were Known Past The Point Of Necking What Course Hero

Tensile Testing Data Sheet Please Fill In Your Name Group Members Data And Instructor S Name Mark Gage Length Indents Using The Hammer Measure The Ppt Download

Engineering Stress Strain Curve Part One Total Materia Article

Yield Stress And Strain Calculations Based On 0 2 Offset Method Of Download Table

Importance Of Yield Strength Plastic Deformation To Civil Engineers

What Is 0 2 Of Offset Method In Yield Strength Quora

Strength And Stiffness Characteristics

コメント

コメントを投稿